HANDCRAFTED SUNGLASSES MADE IN THE USA SINCE 1973

At Randolph, craftsmanship is more than a tradition—it’s our legacy. Since 1973, every pair of Randolph eyewear has been meticulously handcrafted in our Massachusetts factory. We prioritize sourcing materials from within the USA whenever possible. We also seek out the highest-quality components from around the world to ensure every detail meets our uncompromising standards. From initial design to final polish, our skilled artisans bring their expertise to every step of the process. The result? Eyewear that exemplifies exceptional quality, timeless style, and unmatched durability.

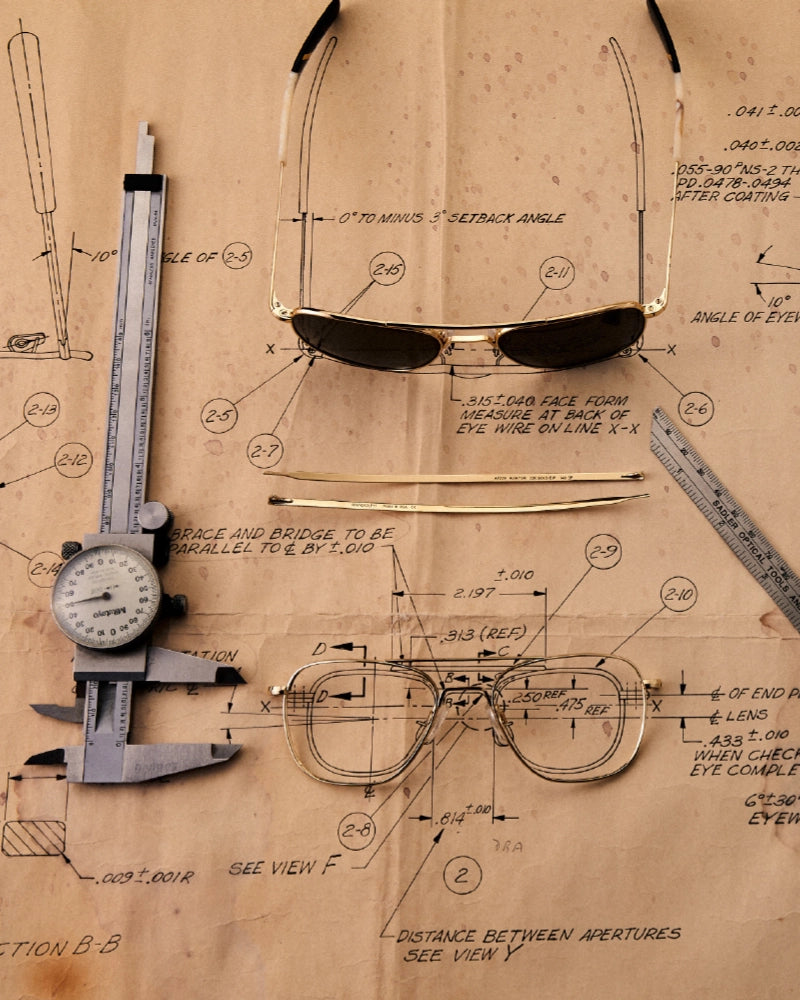

CRAFTSMANSHIP

AND QUALITY

Every Randolph frame is crafted through a meticulous process that involves over 200 precise production stages—most completed by hand. It begins with the finest materials, including corrosion-resistant metal alloys and premium mineral glass lenses. Our in-house frame components are expertly soldered by hand, ensuring unmatched precision and durability. Each pair is then polished to perfection and rigorously inspected to meet our uncompromising standards. This labor of love is what sets our eyewear apart, ensuring it’s built to last a lifetime.

DESIGN

AND INNOVATION

Since 1973, Randolph has been dedicated to crafting eyewear that effortlessly blends functionality with timeless style. Our military heritage laid the groundwork for purposeful design, exemplified by features like bayonet temples—originally engineered for pilots to wear comfortably under headgear. Over the decades, our styles have evolved to meet the needs of a broader audience, embracing contemporary trends while honoring our roots. Through in-house innovation and meaningful collaborations with like-minded brands, we strike the perfect balance between classic and modern, creating eyewear for those who champion individuality and strive to reach new heights.

HERITAGE AND

AUTHENTICITY

A rich military heritage and American roots are central to the Randolph identity. Echoing the spirit of American tradition, with five decades of experience, our family owned and operated business is commitment to excellence, with skill and dedication passed down through generations to craft military-grade eyewear.

FRAME

MATERIALS

Randolph Eyewear is renowned for using globally sourced premium materials, carefully selected for their superior quality and performance. Each frame is crafted from corrosion-resistant metal alloys. Each frame is crafted from corrosion-resistant metal alloys, such as Monel and stainless steel. Monel is celebrated for its exceptional blend of strength and flexibility, ensuring that our frames maintain their shape, comfort, and durability in even the most demanding conditions. Similarly, stainless steel is prized for its remarkable resistance to rust and tarnish, as well as its lightweight properties, offering wearers unmatched durability and all-day comfort. For our acetate, we use cellulose-based material that is sustainably derived and prized for its rich color, exceptional durability, and luxurious finish, embodying Randolph's commitment to both style and sustainability. To further enhance durability and quality, all Randolph frames are coated with advanced finishes applied in the USA. We partner with local experts, including Tanury Industries in Rhode Island for electroplating precious metals and Rampart Coatings in Florida for Cerakote finishes. These meticulous techniques deliver flawless finishes, ensuring our eyewear combines exceptional performance with timeless, lasting elegance.

LENS

TECHNOLOGY

Randolph lenses are designed to deliver superior clarity, durability, and protection. Our SkyTec™ mineral glass lenses are celebrated for their exceptional scratch resistance and crystal-clear optics, while our SkyForce™ nylon lenses, 40% lighter than glass, provide premium visual clarity without compromising durability. To further enhance performance, we’ve developed advanced lens coatings that optimize vision, block harmful UV rays, and ensure long-lasting eye protection. With Randolph, you experience unparalleled optical precision and comfort, crafted for any adventure.

DESIGN

PHILOSOPHY

Our philosophy is the perfect blend of functionality, comfort, and style. While the Authentic Aviator style remains our hallmark, we’ve expanded our design horizons to embrace contemporary shapes and aesthetics with a signature Randolph twist. Throughout, our unwavering focus on durability, clarity and comfort remains steadfast, ensuring each style meets the highest military standards.

ICONIC AND

AUTHENTIC STYLE

Rooted in military heritage, our iconic bayonet temples allow for easy removal with helmets or headgear, with minimized pressure points for enhanced comfort.

Every pair of Authentic Aviators are crafted to not only meet, but surpass, U.S. Military Standards.